27 May 2025

The challenges: navigating the complexities of remote mining

Banpu lacked a reliable system to track the movement and status of high-value assets like mining trucks traversing extensive routes between mine entrances and storage facilities. This resulted in difficulties in asset accountability and operational efficiency.

Monitoring worker safety in remote, connectivity-deprived zones was a critical concern. Ensuring prompt response to emergencies and maintaining oversight of personnel was increasingly difficult without real-time communication.

Mining operations required continuous surveillance of environmental parameters—weather conditions, land stability, and air quality (including PM2.5 dust levels)—to uphold safety standards and regulatory compliance.

Traditional communication solutions proved impractical in these isolated locations, necessitating a specialized wireless infrastructure that could deliver reliable, scalable connectivity and data processing at the edge.

Deploying Veea’s hyperconverged edge network

To surmount these challenges, Banpu collaborated with ICT, which partnered with Veea to develop a comprehensive, cost-effective, and scalable wireless and IoT ecosystem. The integrated solution combined Veea’s hyperconverged edge network platform with IoT gateway capabilities, tailored to the unique demands of remote mining environments.

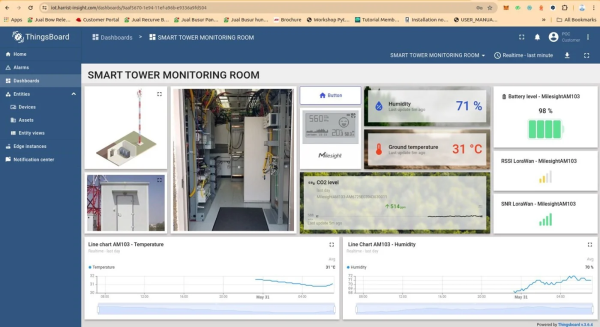

Key components of the Implementation included the establishment of robust wireless links from the mine entrance along access roads to storage facilities, ensuring continuous, real-time communication for asset management and operational coordination. Veea deployed multi-purpose edge hubs integrated with LoRaWAN sensors to monitor environmental parameters such as weather conditions, land movement, and PM2.5 dust levels, facilitating proactive safety measures. Local data processing was enabled at the edge, reducing latency and allowing immediate decision-making—crucial for timely responses to environmental or operational alerts. Veea also developed a resilient network mesh that extended connectivity across the mining site, with seamless integration to cloud platforms for long-term data storage, analysis, and reporting.

A proof of concept (PoC) was conducted at one of Southeast Asia’s largest coal and gas mining sites in East Kalimantan. After rigorous testing—evaluating WiFi performance, LoRaWAN sensor predictions, and sensor data integration through ChirpStack—the solution was successfully deployed across the site.

Unlocking remote mining potential with advanced connectivity

Real-time monitoring of mining trucks is now standard, providing Banpu with full visibility of high-value assets, optimizing fleet management, and reducing theft or misplacement risks.

Continuous environmental and security monitoring—including video surveillance, environmental sensors, and worker safety devices—has significantly improved Banpu’s ability to safeguard personnel and assets, even in the most isolated zones.

By consolidating multiple functions—connectivity, IoT gateways, edge computing, and cloud access—within a single hyperconverged platform, Veea’s solution reduced deployment costs and simplified infrastructure management.

The scalable, flexible architecture positions Banpu to adopt further innovations such as advanced automation, predictive maintenance, and expanded IoT applications, establishing a future-ready digital infrastructure. Banpu’s collaboration with ICT and Veea exemplifies how cutting-edge wireless and IoT technology can transform remote mining operations. By bridging connectivity gaps and enabling real-time data-driven decision-making, the company has enhanced safety, operational efficiency, and environmental compliance—setting a benchmark for smart mining in challenging environments.